The art of cartridge manufacturing

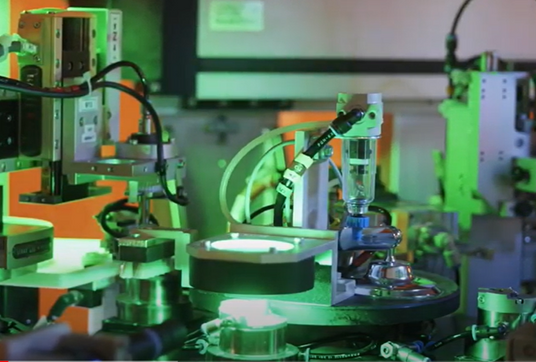

The power of automation technology

Mastering emerging technologies

Delivering high-quality audio reproduction

Manufacturing of coils

The art of cartridge manufacturing

The power of automation technology

Delivering high-quality audio reproduction

Manufacturing of coils