Tradition meets innovation

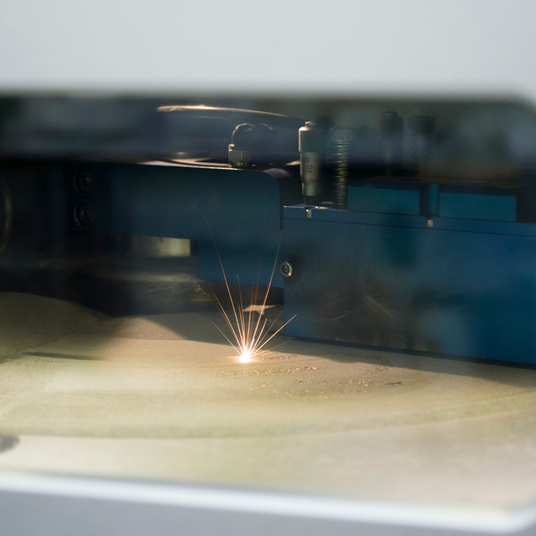

Laser precision

redefining audio

Unparalleled listening experience

Revolutionizing sound

A celebration of a significant milestone

A bigger creative desig space

Distinctive aesthetic

The consolidation of components

Tradition meets innovation

Laser precision

redefining audio

Unparalleled listening experience

A celebration of a significant milestone

Distinctive aesthetic

The consolidation of components